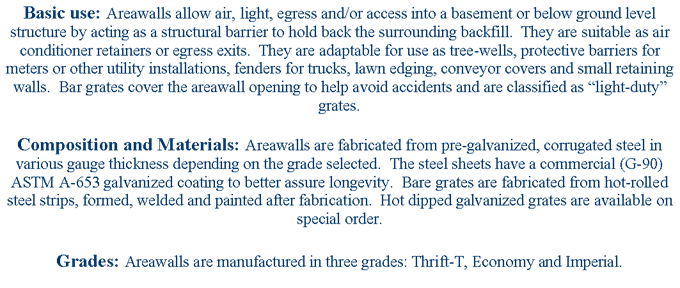

|

· Hybrid galvanized frame with UV protected clear XL polycarbonate materials. You can see the strength™. Powder coated option available on special order. · Engineered as fully self-supporting requiring no bracket mounting into the home's siding. · Innovative squeeze-and-size spring clip fastening installs on new and retrofit applications accommodating areawalls distorted from original factory dimensions. No special sizing required. · Industries only safety retainer-hinge lanyard system allowing up-and-forward pivot for access. Prevents cover from falling in on expensive egress windows or on occupants attempting to exit. · Designed to install over any manufactures' areawall regardless of profile. Unique vented design eliminates the greenhouse effect common in non-vented products. · Sloped for drainage. Unlike flat covers, water will not accumulate in the window well. · No assembly required. Tool free installation. · Designed to be compatible with egress ladders required by modern residential building codes. · Designed with the DIY homeowner in mind. Protect and enhance your basement windows. · Tested to 500 lbs, rated for 350 lbs. static load. · Meets all specifications as provided by the IRC2006 egress code. · Limited lifetime warranty. |

|

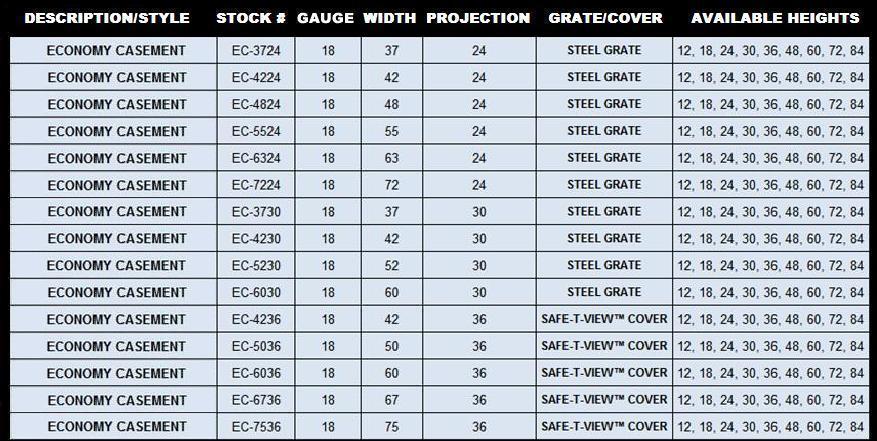

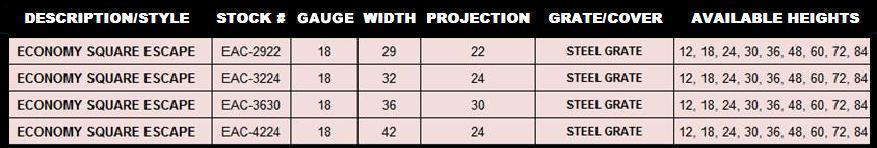

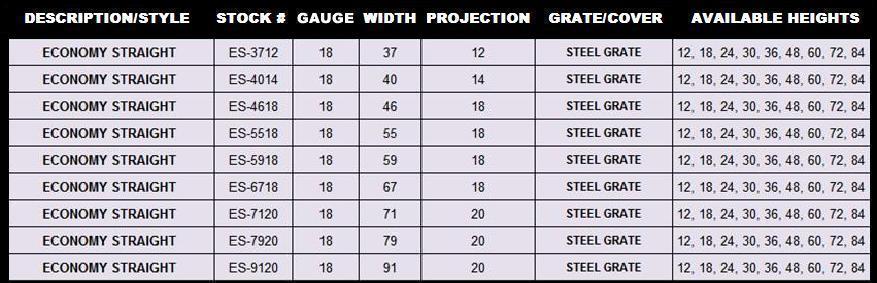

Designed to fit nearly flush with the top edge of SPC's Areawalls. Prevents pedestrian traffic from potential hazard of open window wells. Manufactured from 3/16" x ¾" steel strip bars set 2" on center welded to 1" bar frame. Painted industrial gray primer for rust resistance. Available in straight, round or casement square styles in sizes to fit any of SPC's standard Areawalls. |

|

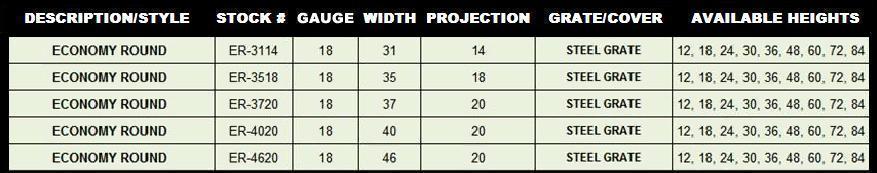

Please follow these steps to process your inquiry quickly and efficiently:

1. Choose a size from the list provided: Make a note of the part number, for example: EC-4236 @ 30" in height, or EAC-4224 @ 24" in height. 2. Have the delivery address and zip code ready. 3. Call us at (800) 323-7055 Monday - Friday 8AM to 5PM, CST.

Please note: Window Wells are not in stock and must be made to order.

|

|

Frequently Asked Questions

Q. Do you have any distributors anywhere else in the United States? A. At this time, we only sell and ship direct from Minneapolis, MN.

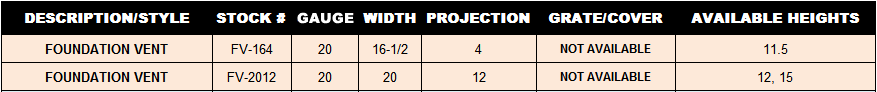

Q. Are these all "Stock" items and how long will it take for me to receive them? A. All window wells except for "Foundations Vents" are made to order. Generally it will take 7 -10 business days for delivery.

Q. How do you ship the window wells? A. The majority of our wells will ship via Common Carrier, i.e., “Old Dominion Freight Lines”. Shipping costs will vary on quantity ordered and what type of address they will be shipped to: Residential or commercial.

Q. Does Residential Delivery cost more than Commercial Delivery? A. Residential Delivery costs more due to a lack of loading/unloading facilities.

Q. What is considered a “Commercial” address? A. An address is only considered “Commercial” if there is a loading dock.

Q. Can you ship these items through UPS? A. Yes. Although very few of our products meet UPS size requirements, we strive to find the most cost effective means to ship all orders.

Q. Do you except credit cards over the phone? A. We accept all major credit cards; However, we also except "checks" or "money orders" but we cannot ship the item until checks have cleared; Therefore prolonging the lead time on the items.

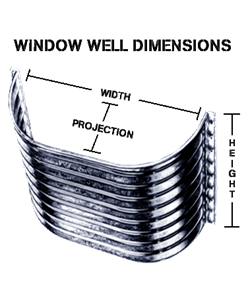

Q. What are you sizing recommendations? A. After checking for egress compliance we recommend to size the window wells width to have a 3" overlap on both sides of the masonry opening. Window buck mount require actual hole to hole measurements. Vertical height is determined by the finished grade allowing for suitable slope away from the foundation for water management. Please order enough areawall height to have 10-12" below your windowsill and 2" above your finished grade.

Q. How do I install a window well? A. The areawall should extend beyond the window rough opening by 3” both sides. Some building codes may require additional clearance. The top of the Window Wells should extend approximately 2” above the established grade line and down at least 12” below the windowsill. If in doubt, go with a higher wall since extensions are difficult to attach. Fill the space below the window well with select gravel for drainage. Flanges should be attached to the foundation wall at sufficient points (12” centers minimum) to assure structural stability. Use masonry nails, self-drilling anchors or other approved fasteners. Select backfill material should be used, such as granular with some clay that is free of large rock and earth clods and should not be frozen material, sod, cinders or other active soils. The load carrying capacity of the Window Wells is largely dependent upon proper backfill procedure. The fill should be placed evenly around the areawall in 12” layers using ordinary compaction making sure the shape is not distorted. On larger sizes a 90 % density factor may be desirable. Compacted fill around the outside of the areawall should be at least 12”, or one-half of areawall projection. We recommend supporting the areawall inside face during the backfilling procedure. Supports should be left in place until construction activity ceases. On larger and deeper Window Wells, care should be used in selecting the grade and style |